• Thin film coating and product development in regions (VIS, NIR, SWIR, MWIR, LWIR)

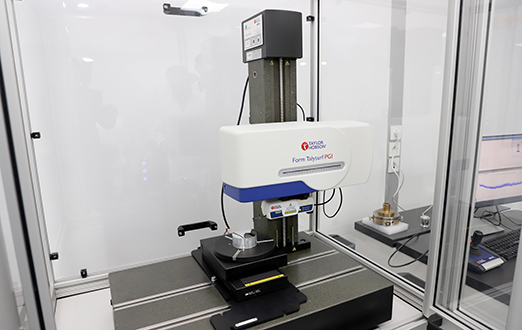

• Hanil Vacuum 900DA PVD system

• 900 mm chamber size

• 10-7 Torr High Vacuum Pumping

• Chamber temperature up to 300 degrees

• Dome type rotation system for substartes

• Electron Beam, Ion Beam and Resistance heat sources

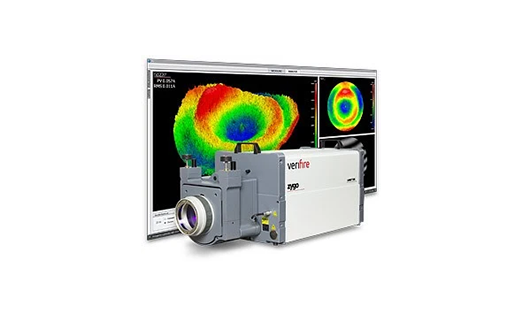

• Tavg > 98% - Ravg < 0.4% @ 3.6–4.9μm

on Ge, Si,&-CaF2 substrates

In the defense industry

• Forward Looking Infrared (FLIR) used in military vehicles (fighter jets, drones, etc.) and equipment

• Thermal scanner warhead (heat-seeking) system

• Night and thermal vision camera applications

Other industrial applications

• Safety technology; filters for gas analysis, mining, alcohol measurement, building technology

• Environmental technology; biogas analysis, greenhouse gas analysis, emission monitoring

• Medical technology; patient and anesthesia monitoring

• Agriculture; biogas plants, quality control

• Flame detection; pyroelectric detectors

• Infrared spectroscopy; chemical analysis, e.g. alcohol, sugar and water content